Prevent Inrush Current with PTC and NTC Thermistors

PTC and NTC thermistors can provide inrush current protection in various equipment, machinery, and systems. Inrush current affects a wide range of products, from transformers to motors, and electronics from power supplies to inverters.

Inrush current becomes further complicated by systems that switch on and off quickly, such as welding equipment and HVAC systems. This post will give you a brief overview of the topic. For more information, you can read the full article here.

An uncontrolled flow of inrush current can damage the diode bridge and link capacitor, disabling the conversion of AC to DC current. This can lead to system failure.

What is Inrush Current?

Inrush current is a surge of current when an application is powered-up. It is created by different electrical effects. The powering on of power supplies requires the charging of capacitors. The powering on of a transformer creates an inrush current during its initial magnetizing.

Why Manage Inrush Current?

Inrush current can reduce the effective operating life of the equipment and damage the system. Fortunately, NTC and PTC limiting thermistors can properly manage this. Electrical and mechanical stresses can occur from this current surge which can decrease equipment lifespan.

What is an NTC-based Limiting Thermistor?

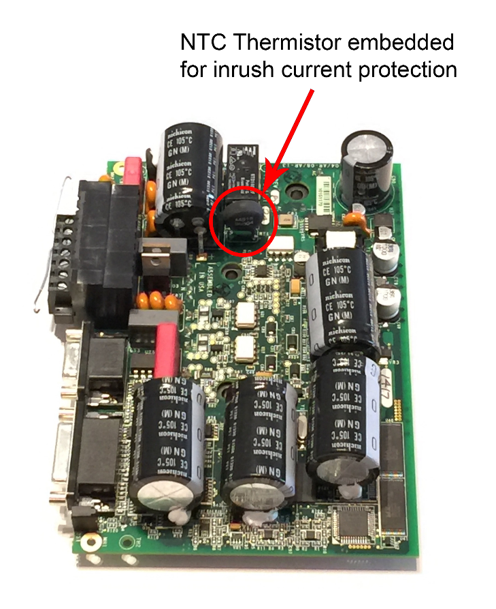

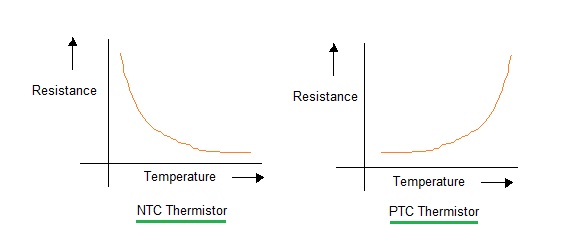

NTC stands for Negative Temperature Coefficient. The NTC thermistor provides variable resistance based on temperature. As temperature increases, the resistance drops from high to low and allows current to pass through. When used for inrush current mitigation, it provides an additional series resistance at power on. As the thermistor self heats with current flow, the resistance drops to a negligible amount during steady-state, allowing normal current flow.

NTC thermistors are the most commonly used thermistor. They fit a wide range of applications, including automotive, military, industrial, and emissions controls. Various items around your home contain NTC thermistors, including your oven, air conditioning, and fire detector.

For an NTC thermistor, as temperature increases, resistance decreases. For a PTC thermistor as temperature increases, resistance increases.

What is a PTC-based Limiting Thermistor?

PTC stands for Positive Temperature Coefficient. The PTC thermistor also provides variable resistance based on temperature. As temperature rises, resistance increases from low to high and blocks the overcurrent. Specific scenarios require a PTC thermistor over an NTC thermistor. These include equipment with a near-zero reset time, extreme temperature conditions, and systems that experience frequent shorts.

References:

Special Thermistors Limit Inrush Current