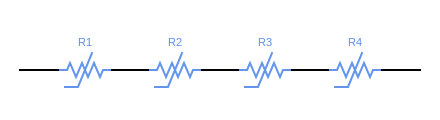

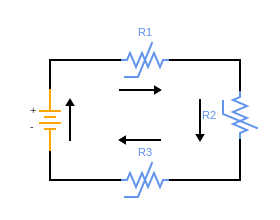

Connecting in Series – Recommended

When you connect NTC thermistors in series for inrush current control, you gain several important benefits. Most importantly, the energy is distributed across all the units evenly, which extends the life of both your application and it’s components.

Need a Refresher on What a Thermistor is? Click Here.

Furthermore, another benefit of connecting NTC Thermistors In Series is that in doing so, it raises their combined resistance, lowering the maximum inrush current. NTC thermistors naturally decrease in resistance as the temperature increases. So, during startup when the system is cold, they collectively offer higher resistance, reducing the surge of current. This keeps sensitive components safe and power supply systems free from damage.

In short, connecting in series for inrush current control offers energy division among thermistors, increased resistance for lower maximum inrush current, and enhanced system protection. It’s a reliable method for managing inrush currents in applications like power supplies, electric motors, and electronic devices.

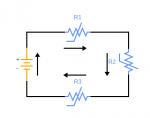

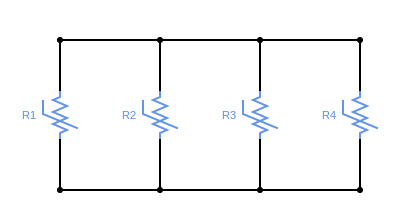

Connecting in Parallel – Not Recommended

Engineers typically avoid using NTC thermistors in parallel configurations because of their unique characteristics. In a parallel setup, each NTC thermistor follows its own temperature-resistance curve. This means that the one with the lowest resistance at a given temperature controls the current path, while the others exert less influence. As a result, uneven current distribution can occur, potentially leading to excessive inrush currents and system damage. Read more about NTC Thermistors Temperature Compensation Circuits Here.

Furthermore, a parallel configuration presents thermal stability challenges. NTC thermistors generate heat during operation, and in a parallel setup, this heat dissipates unevenly. This can result in temperature imbalances and inconsistent resistance behavior, further compromising their effectiveness in limiting inrush currents.

In short, using NTC thermistors in parallel for inrush current protection is generally discouraged due to decreased overall resistance, uneven current distribution, and compromised thermal stability. Instead, the preferred method is the series configuration, which allows NTC thermistors to collectively limit inrush current, ensuring a more controlled and reliable system operation.

Find What NTC You Should Use in Your Application Here.

Ametherm thanks you for taking the time to read our Blog posts. If you have any questions, please contact us, or fill out the form below and we will respond right away.

Visit Our Distributors to See Availability of Our Inrush Current Limiters