Large power users require mitigation of inrush currents as part of overall energy management strategy. Industrial automation with motor drives and logic controllers, high voltage power supplies feeding industrial robotics and solar panel arrays with large capacity power inverters all require inrush current limiting.

Overview

Inrush current is the momentary surge of current created when power is turned on to motors, transformers, power supplies and heating elements. These current surges are usually less than one second in duration but are many times the magnitude of the normal operating current.

The more power required by industrial equipment, the higher the inrush current. The power required by some equipment can create inrush currents which are difficult to manage. Input power levels rated in kW or kVA can create inrush currents measured in the hundreds of amps and energy in thousands of joules.

These high inrush currents can induce electrical and mechanical stresses in both production and facilities equipment. Inrush currents can cause nuisance faulting of circuit breakers, contactor welding, premature component failures and even erratic equipment behavior. They can also require larger building mains capacity and contribute to shorter maintenance and repair schedules.

Thermistor inrush current limiters present a resistance to inrush current when the circuit is energized. This added resistance acts to quench the inrush current. The thermistor’s resistance decreases dramatically following the inrush, allowing the steady state current to flow with very little resistance. This effect provides inrush current protection, yet allows efficiency during normal operation.

Ametherm thermistor inrush current limiters are used widely in major appliances and consumer electronics to reduce inrush current. They are found microwave ovens to power tools and tablets to giant stadium displays.

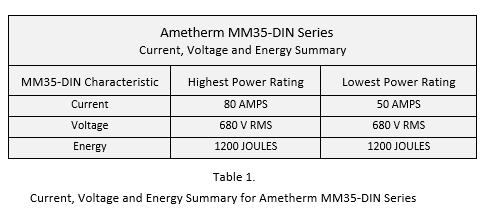

With the development of the Ametherm MM35-DIN Series, thermistor inrush current limiters can now handle industrial-size power requirements. A summary of the current, voltage and energy ratings for the Ametherm MM35-DIN Series is shown in Table 1.

The MM35-DIN Series is specifically designed for use with DIN blocks, so mounting within a power control box requires only a screwdriver. Whether three-phase or single-phase power, the MM35-DIN Series is ready for your industrial application. Illustration 1 shows the use of MM35-DIN in three-phase configuration mounted on a DIN rail.

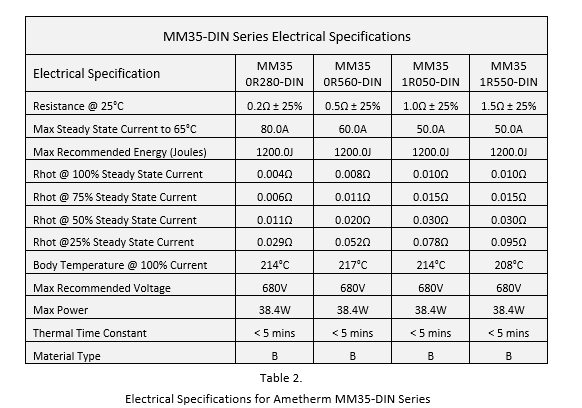

With continuous current ratings from 50A to 80A at 680V RMS and energy to 1,200 joules, the Ametherm MM35-DIN Series inrush current limiters can handle power levels found in the industrial environment. Table 2 shows the MM35-DIN Series electrical specifications. These include the cold and hot resistance, maximum steady state current, maximum energy rating and operating temperature.

Applications

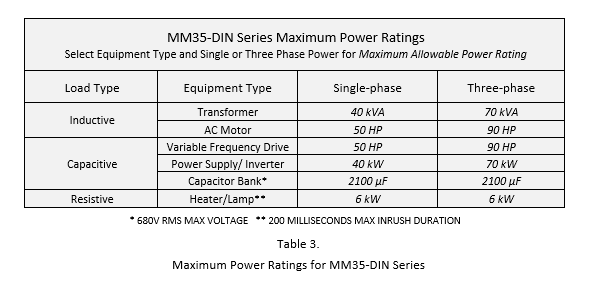

Ametherm MM35-DIN Series can be used to limit inrush current for industrial equipment which requires either single-phase or three-phase power. The power rating of the MM35-DIN Series must be more than the power rating of the equipment to be protected. Power rating for the device can be found on the manufacturer’s equipment tag or in the tech documentation.

Use Table 3 to determine the maximum allowable VA, HP or wattage rating which can be used with the MM35-DIN Series. First, select the row containing the type of equipment to be protected: transformer, AC motor, power supply, inverter, heater, etc. Then locate the appropriate single-phase or three-phase power column. Read across the table to determine the maximum power level that the MM35-DIN will handle. For example, an AC motor with single-phase power must have a power rating of 50 HP or less for the MM35-DIN Series inrush current limiter to provide protection.

*** DO NOT ATTEMPT TO USE THE MM35-DIN SERIES WITH ANY EQUIPMENT WHICH EXCEEDS THE POWER LIMITS SHOWN IN TABLE 3 ***

Additional Considerations

Body temperature and heat dissipation of components are a consideration for many applications. Managing heat loads in power control cabinets is important if electronic controls are co-located inside. Power dissipation in watts for each of the MM35-DIN Series are shown in Table 2 under “Max Power.”

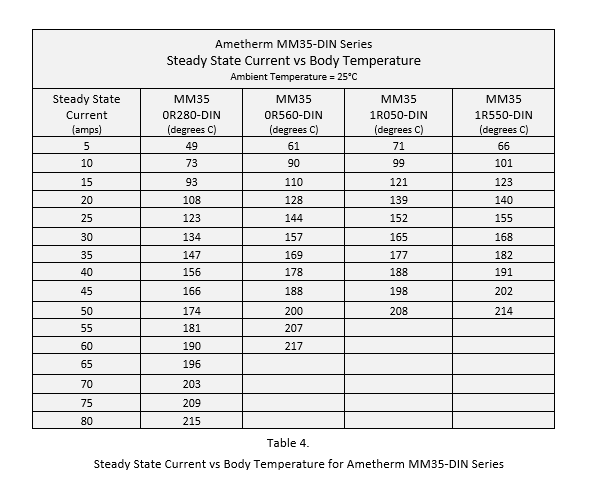

Body temperature at one-amp increments of steady state current are shown in Table 4. One potential advantage of the MM35-DIN Series is the lower body temperature at a given steady state current when compared to other inrush current limiters.

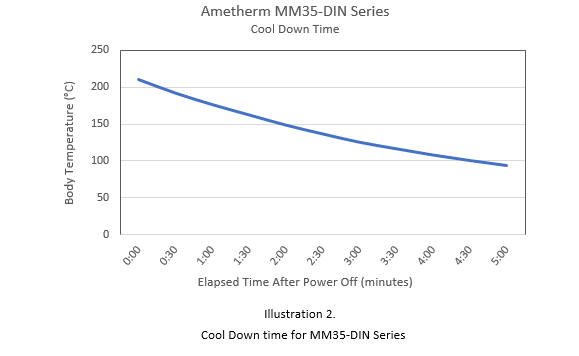

The duration that power is off following the period that power was on can affect the ability of the inrush current limiter to quench the next inrush current. The MM35-DIN Series inrush current limiter cools according to the Thermal Time Constant rating as shown in Table 2. This is the time required to cool 62.3% of the body temperature after power is turned off. This duration is necessary for the inrush current limiter to regain sufficient resistance to be ready for the next inrush current. A curve of temperature vs duration after power is turned off is shown in Illustration 2.

Calculations

To select the appropriate MM35-DIN Series part it will be necessary to determine the cold resistance, maximum steady state current and maximum energy required by the application. Table 5 provides links to the Ametherm web page for each of the six possible calculations required. Select the column indicating whether the equipment is inductive, capacitive or resistive. Then select the row indicating whether it requires single-phase or three-phase power. Click on the link to provide sample calculations required to select the appropriate MM35-Din Series.

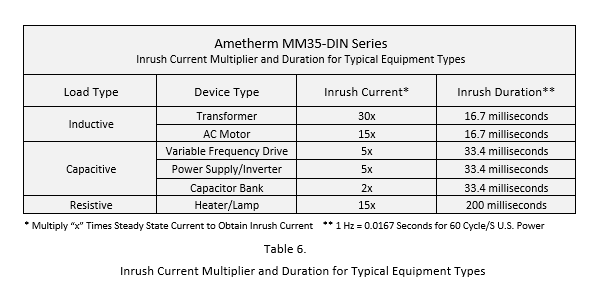

The information shown in Table 6 will be necessary to calculate the joules requirement for selection of the appropriate MM35-DIN Series. Each device type creates an inrush current of a specific magnitude and duration. The inrush current magnitude is expressed as a multiplier of the device’s steady state current. For example, inrush current to an AC motor is 15 times its steady state current.

.

Calculations for cold resistance, maximum steady state current and maximum energy will determine the appropriate MM35-DIN Series for the application. Use these ratings to select the appropriate MM35-DIN part from Table 2. For example, first select the part in Table 2 which has the equivalent or next higher resistance indicated by the calculation. If your calculation indicates 0.75 ohm resistance, select the 1.0 ohm MM35 1R050-DIN from Table 2. Next, confirm that the calculated steady state current does not exceed the 50A maximum steady state current rating of the MM35 1R050-DIN. Lastly, confirm that the calculated energy does not exceed the 1200 joules energy rating of the MM35 1R050-DIN.

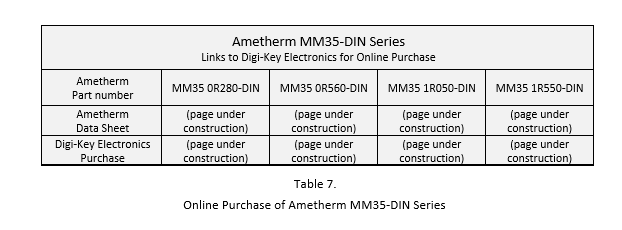

The MM35-DIN Series are available from Digi-Key Electronics (Digi-Key.com). Using Table 7, select the Ametherm Part Number from appropriate column, then click on the link below to provide Ametherm data sheet or Digi-Key pricing and shipping options.

As always, thanks for reading! If you would like to learn more about our new MM35-DIN series, contact us. We invite you to test them for yourself.